Precision, traceability, and efficiency are vital standards in the pharmaceutical industry. One of the largest pharmaceutical automation solution companies based in Singapore, a stalwart operating over several decades developing and providing industry-specific automation solution for its customer to support greater efficiency, create complete transparency and shape the future of health care.

The challenge

They are looking for reliable Thermal Transfer ribbon solution for their medication tag and packaging label to further expand their business in Asia Pacific, starting off in Singapore. Healthcare packaging plays a critical role in pharma traceability because it provides information on the medication identity, origin country manufactured and destination to ensure it can be used to track and trace at every stage of medical supply chain, from distribution to dispensing of medication to the patient.

They list out their requests to our partner in Singapore:

- Versatility of the ribbon – one ribbon for coated paper, Matte white synthetic, White synthetic

- A ribbon with higher durability and rubbing resistance, indispensable for medication tag and packaging labelling with a competitive pricing.

- High durability, able to remain crisp and sharp information throughout the lifecycle.

- Applicable with their modified printers – Intermec

- Shorter lead time

The solution

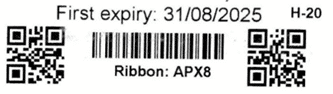

Understanding the critical nature of their requirements, our TTR experts were presented with the opportunity to introduced them our newly released wax-resin thermal transfer solution – APX 8 .

But why APX 8?

Through extensive print tests together with our local partner and a deep dive into the challenges mentioned above, APX 8 showcased unparalleled strength and resilience. The inherent characteristics of APX 8 positioned it as the perfect match for their stringent labeling requirements.

- APX 8 is capable of withstanding scratches and smudges on the matte synthetic, synthetic pouch and coated paper that applied on the medication tag.

- With primary features of APX 8, such as its sharp printing quality, the information printed on the medication tag shows excellent readability after conducting scientific tests in ARMOR-IIMAK Print lab.

- The barcode and information printed on the label with APX 8 display crisp and dark imaging, ensuring high visibility to guarantee the traceability of the medication.

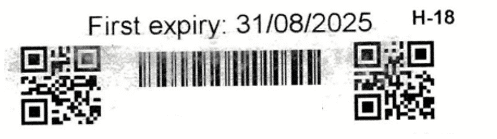

Wax-Resin ribbon in the market after 10 cycles of abrasive test under extreme condition

on a Matte White Synthetic label

Why ARMOR-IIMAK and our partner?

In addition to addressing challenges and meeting requirements, ARMOR-IIMAK and our partner can highlight the following:

- We further solidified our partnership through premium services and an instantaneous response time.

- We provided comprehensive print studies and test reports, allowing for a side-by-side comparison of APX 8 with other products in the market to aid the decision.

- Being located in Singapore also translates to into shorter lead times and lower shipping costs, giving them a logistical edge.

- Our commitment to best pricing ensured that not only did our solution excel in quality of the product, but it also offered superior value.

Our ARMOR-IIMAK Asia sales team, along with our local partner, had absolute confidence that the inkanto ribbons provide a perfect solution that not only met all the challenging requirements of this company’s labeling needs but also exceeded expectations. This confidence translated into a substantial order for APX 8 as their initial purchase.

As they expand their operations and enhance efficiency in the coming year, the adoption of APX 8 as the preferred wax-resin ribbon sets the stage for a future where excellence in labeling becomes synonymous with them.